Diseño y desarrollo de objetivos

Optical and optomechanical design, assembly and validation

The ESRF (European Synchrotron Radiation Facility) contracted ASENSE Europe for the design, development and manufacture of three unique, custom-made lenses to integrate into its synchrotron beamlines for its research.

ASENSE designed and manufactured three different objectives: 0.5X, 400mm and 150mm.

From concept design to manufacturing

ASENSE’s work began with an initial feasibility study of the systems. From this study, our experts in optical design optical design designed and developed each of the targets required by the Synchrotron, including all critical phases for the success of the project:

- Optical tolerance analysis.

- Opto-mechanical design

- Custom manufacturing of lenses, barrels and other opto-mechanical components.

- System assembly and validation of the parameters required by the client.

During the design phase, materials were carefully selected to meet all requirements. For the validation phase, ASENSE designed and assembled its own MTF bench, tailor-made for each target, to ensure maximum accuracy in quality testing.

The results – customer satisfaction

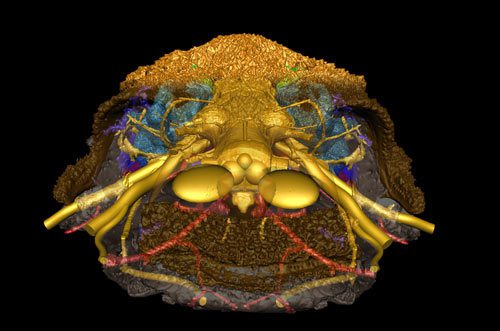

The results were a complete success. The custom-made lenses delivered exceeded the ESRF’s expectations, and months later they sent us images of the results obtained thanks to the lenses we designed and manufactured. ASENSE recently visited the ESRF facilities and saw that the three lenses are in use, operational, and delivering the same excellent results as on day one.

Do you have any questions?

If you enjoyed this post on “Design and Development of Objectives,” you might also be interested in reading “Optical Design for Laryngoscopy.”