OCCIM-DEV Program

Integration of combined computational imaging and image processing for transparent micro-devices

Non-destructive inspection for microfluidics and microdevices

ASENSE received funding for the development of its FASTTEST instrument, a novel system for the non-destructive 3D inspection of microfluidic and other microdevices, through the Horizon 2020 SME Innovation Associate program, with its proposal “Optimized integration of Combined Computational Imaging and image processing for transparent Micro-Devices” (OCCIM-DEV).

Objective: To develop an instrument for the inspection of microfluidic chips and other micro-components.

Specializing in the design and development of precision optical systems, ASENSE is also a strongly R&D-oriented company, constantly working to expand its innovation capacity, both internally and with clients and their projects. Over the past year, we have been working on the development of an instrument for the non-destructive 3D inspection of microfluidic chips and other micro-scale devices.

Hiring a Research Associate (RA) was a strategic and key step in advancing and progressing the development of our metrology instrument, FASTTEST, to achieve a more integrated final solution.

Our AI: Who is it?

Marino Maiorino is a PhD specialized in the characterization of solid state detectors for imaging applications. He has extensive experience in digital signal processing, control software development and algorithm implementation and optimization. His main task has been the improvement of algorithms and high-tech image processing. Marino has joined the R&D department of ASENSE, and has led the integration of the first FASTTEST system for nondestructive inspection of microfluidic chips.

Program development: software integration and optimization of the various assemblies that make up the FASTTEST instrument.

The main work of the OCCIM-DEV project has focused on software integration and optimization of the various components and subsystems that make up FASTTEST. OCT (optical coherence tomography) and FFT (Fast Fourier transform) measurements, which allow for depth measurement, have been successfully performed and calibrated.

Combination OCT + artificial vision system

The OCT data acquisition speed has reached 40,000 profiles per second. A user-friendly interface has also been developed, allowing the user to select which OCT path to scan. Similarly, the system can self-configure and perform different measurement operations depending on the path entered by the user.

On the other hand, the machine vision system is capable of recognizing the patterns that will be used to automatically guide the OCT beam toward the critical regions and parts of the microdevice to be inspected.

Currently, FASTTEST has been demonstrated and tested several times with potential customers. Specifically, the system is being adapted for a medical device manufacturer that wants to apply the technology to solve a specific quality control problem that hasn’t been addressed to date. The ability to adapt the software to the needs of each customer and each problem has increased the system’s market opportunity.

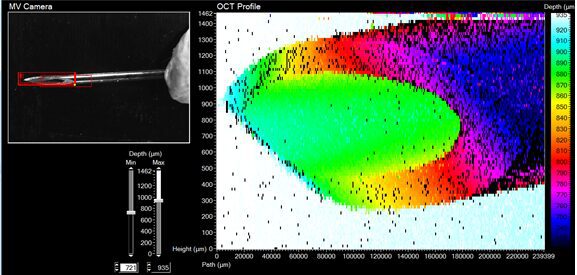

Some results: a 3D map of the inspection area of a micro-device type

The main panel shows a 3D map of a syringe microneedle portion. Using the software, the area to be inspected is selected, and the same software reconstructs the depth map in “false” colors. Each color corresponds to a specific depth value, according to the color scale shown on the right side of the image:

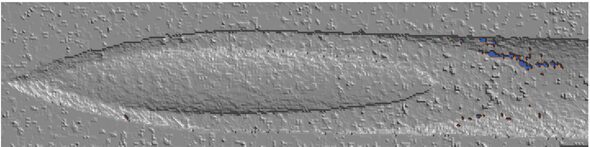

Below is the same information, manipulated with external software:

Significant advances and improvements to the FASTTEST instrument for non-destructive micrometric inspection

The collaboration between Marino Maiorino and the rest of ASENSE’s professionals has enabled significant improvements to FASTTEST, placing this equipment beyond the state of the art of other technologies for non-destructive inspection at the micrometer level.

The 3D measurement rates achieved, combined with the drastic reduction in data load, result in equipment that matches the production rates of an automated system, a result that has never been achieved before.

As a result, manufacturers of microfluidic chips or other microdevices can integrate the system into their production lines, improving manufacturing and quality control. Thanks to the real-time data, manufacturers can quickly detect problems or alterations in the manufacturing process, resolve them, and reduce the number of non-conforming or defective products.

FASTTEST It is a completely autonomous system and, as such, has a comprehensive set of automated diagnostic tools for reliable hardware monitoring.

FASTTEST also provides a guarantee of quality for microdevice end-users. Currently, the primary market for microdevices and microfluidic chips is the medical sector, with the rise of disposable point-of-care devices. Therefore, the long-term impact of FASTTEST will be beneficial to the safety and health of all citizens.

However, this major breakthrough in the development of FASTTEST for non-destructive 3D inspection of microfluidic chips and other microdevices has been made possible through the H2020 SME Innovation Associate Programme (reference no. 739648), funded through the Executive Agency for Small and Medium-sized Enterprises (EASME), established by the European Commission to manage various EU programmes.