Industrial Inspection

We develop customised optical systems for industrial non-destructive inspection, offering advanced tools for diagnostics and quality control on production lines.

Our solutions help detect defects, ensure structural integrity and optimise processes in industries such as nuclear power, aeronautics, semiconductors and advanced manufacturing. Our non-destructive inspection systems provide real-time information, facilitate early detection of deviations or defects and save time and money.

We integrate laser technologies, image processing and automation, adapting to the specific requirements of each client and guaranteeing maximum precision, efficiency and cost reduction in industrial processes.

Competitive advantages

Competitive advantages of our solutions

- Sub-millimetre accuracy in the detection of micro-cracks, corrosion or structural deviations.

- Adaptability to critical environments: from vacuum chambers to areas with ionising radiation.

- Reduction of operating costs by automating inspections and minimising technical stoppages.

- Compliance with international standards (ASTM, ASME, ISO) for non-destructive testing.

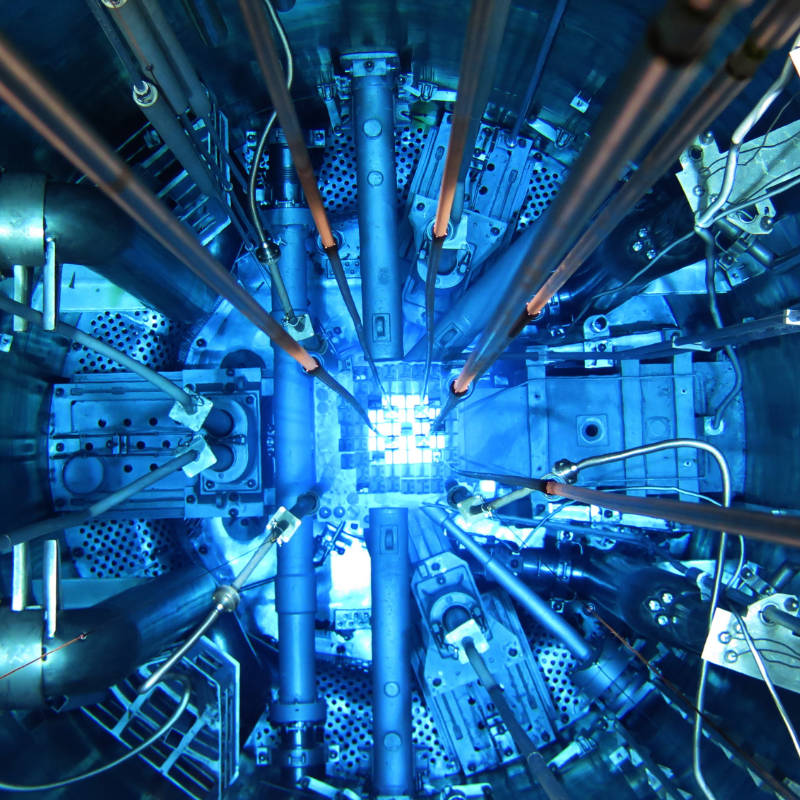

Optronic system

This system, designed entirely by ASENSE, represents a milestone in the safe inspection of radioactive materials.

Take your quality control to the next level with our non-destructive optical inspection solutions. Precision, innovation and reliability in every process.

Phone

+ 34 937 37 98 63

sales@asensenova.com

Address

Carrer Cerdanya, 44

08820 El Prat de Llobregat

Barcelona